As seen in Phoenix Business Journal:

Spirit Electronics Small Business OSAT Grows Around Semiconductor Desert Oasis

Greater Phoenix is a growing semiconductor oasis in the desert. Large-scale commercial manufacturing is making news with new fabs, and supporting businesses like outsourced semiconductor assembly and test provider Spirit Electronics see opportunity for significant expansion.

As the desert cluster grows, an entire ecosystem of support businesses will thrive around it. Spirit fills a niche demand among the local aerospace and defense industry for American-based authorized distribution, assembly and testing services.

Vertically Integrating to Secure the Supply Chain

The A&D demand for defense-grade and space-grade technology adapts more slowly than commercial manufacturing, making it more sensitive to supply chain bottlenecks. Spirit has added solution-focused services that specifically address supply chain constraints. These have included supplier-managed inventory and 3PL services, lead trim and form and robotic BGA solder exchange, MIL-STD-883 testing, radiation testing and circuit card PCB assembly.

Small Business Among the A&D Cluster

Spirit Electronics was founded in 1979 as an authorized component distributor for A&D. Current CEO Marti McCurdy acquired the company in 2017. A veteran of semiconductor testing and the U.S. Air Force, McCurdy was in tune with the supply chain’s testing needs. She grew Spirit’s team to over 40 employees with specialized skills in supply chain management, lab operations, and test engineering. Spirit is now a veteran-owned, woman-owned small business with HUBZone certification.

“When you have an aerospace cluster or a semiconductor cluster like we are growing in Phoenix, services and supply chain businesses move in to support that growth,” explains McCurdy. “Spirit has been part of this local cluster from the beginning, giving us a unique insight into the supply chain. We see the massive opportunity for growth in the Phoenix area and are expanding capacity among our business units to meet those needs.”

A&D has a foundational industry presence in the Valley alongside the burgeoning semiconductor industry. Major companies like Northrop Grumman, Boeing, Honeywell, Lockheed Martin, L3 Harris, and General Dynamics have a significant presence in the Greater Phoenix area and are pushing aerospace technology to new heights.

New Space and New Supply Chain Heights

Among Spirit’s A&D customers, commercial space and satellite programs are revolutionizing space exploration. This New Space industry demands high-reliability electronics to operate numerous small satellites and satellite constellations in addition to deeper space missions with NASA. Spirit provides tailored screening and qualification testing programs to guarantee components and assemblies will be able to function in the harsh temperatures and radiation of the space environment.

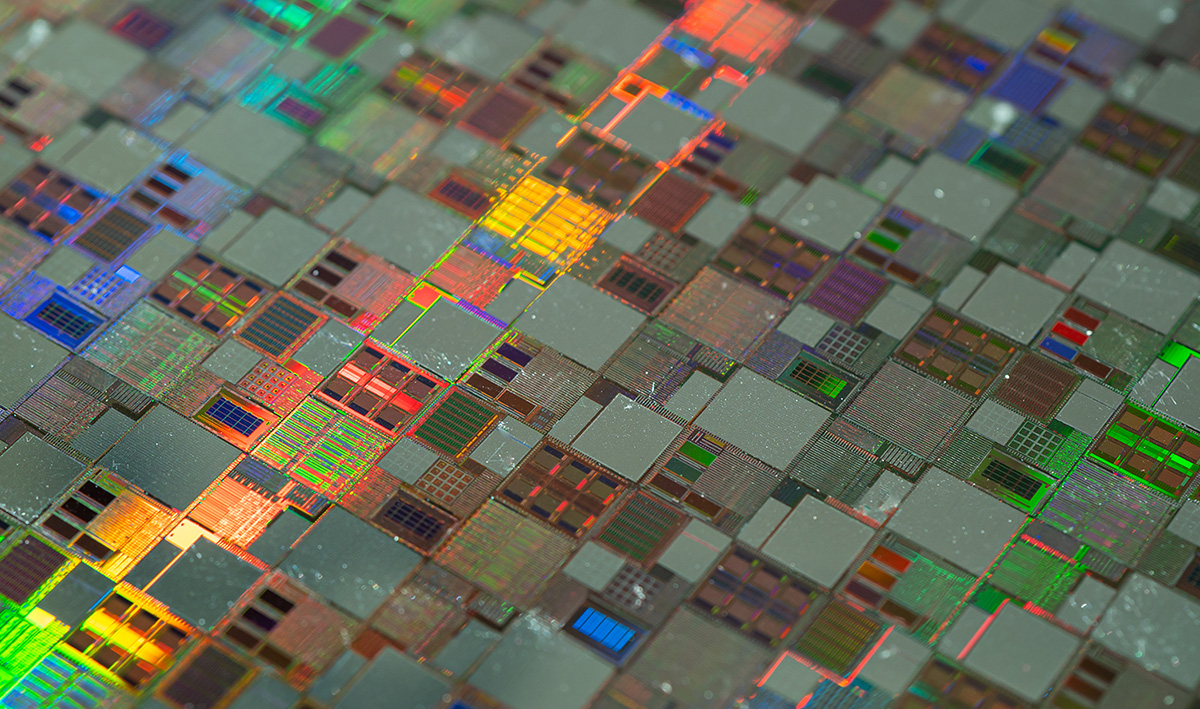

With New Space programs launching faster, Spirit’s end-to-end supply chain services support component sourcing, logistics, testing and PCB assembly to deliver fully qualified and ready-to-use electronics. Spirit also offers application-specific integrated circuits (ASICs) that allow customers to create a custom chip with a faster time to market.

Spirit’s ASIC Programs and Foundry Services

With high commercial demand among major chip manufacturers, Spirit’s ASIC programs offer faster lead times, full qualification and extended manufacturing life for A&D customers with application-specific needs. Spirit can take an ASIC through design, foundry, assembly, test and storage. Spirit offers foundry services through Texas Instruments fabs to support 65nm tech nodes and higher, an essential in the A&D industry.

Spirit’s Small Business Workforce Development

The Spirit team has been the foundation of the company’s growth. While integrating new services vertically, Spirit’s team organization has expanded horizontally, adding skilled technicians, engineers and operational managers to support multiple business units. The team has grown over 280% in 6 years.

Spirit’s team takes pride in the company’s small business agility to offer unique solutions to customer challenges. The team operates under rigorous industry standards while still offering flexible customer service. The Spirit team is highly collaborative, talented and diverse driving innovation in the company.

Spirit added significant recruiting support to continue team growth. The local workforce for semiconductor manufacturing will require specialized education opportunities, and Spirit is growing local partnerships to improve training offerings that directly support critical skills. Spirit has also partnered with ASU to continue expanding the workforce and R&D.

In both workforce and supply chain, the greatest challenge for the local industry is sustainable growth. As a small business, Spirit is excited to continue innovating new solutions to support the business, the team and its customers.