Electronics Analytical Services

Capabilities & Equipment

If your bottom line depends on high-quality analytical services, then a strong lab is your advantage. Choose an electronics analytical lab with a comprehensive set of analytical tools and techniques.

Non-Destructive

- Bench-top testing: Curve Tracers, Logic Analyzer & Data Generator, Oscilloscope, etc.

- Internal and external visual inspections

- Acoustic Microscopy inspection

- Real-Time X-ray Inspection

- IR Microscopy (Thermal imaging)

- X-ray Fluorescence (XRF)

- Micro-FTIR (Organic substance identification)

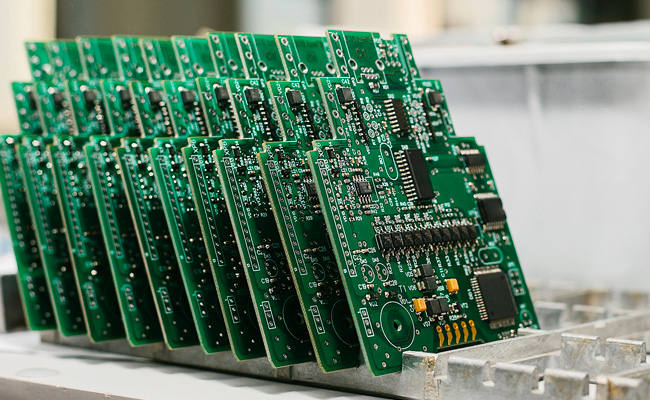

Printed Circuit Board Assemblies

- Visual Inspection (based on IPC specifications)

- Cross-Sectioning

- Potted Cross-Sectioning

- Thermal (IR) Imaging

- Dye and Pry (BGA package) Solderability Analysis

- Hi-Pot & Insulation Resistance Testing

- Heat Resistance, Solderability, etc.

- High-speed & Low-Speed, Diamond Saws

- Parallel Lapping

ICs, Discretes, Semiconductors

- Cross-Sectioning

- Potted Cross-Sections

- Deprocessing – wet, dry and parallel lapping

- Plastic Package Decappers

- Probe Station

- IR (thermal) Microscopy

- SEM Inspection

- Focused Ion Beam (FIB) editing

- FIB Cross-Sections

- FIB TEM Prep and STEM/TEM Imaging

- Photon Emission Microscopy (PEM aka LEM and EMMI)

- Dry etching (oxides and package decaps)

- SIMS and TOF-SIMS

Component Verification

- Visual Inspection: Device markings, dimensions, lead finish, remarking

- Datasheet comparison

- X-Ray inspection

- XRF inspection (RoHS)

- Acoustical inspection

- Decapsulation

- Die inspection (low-mag, high-mag)

- SEM inspection

- Electrical Testing (bench-top)

- Cross-sectioning

- Deprocessing

- Energy Dispersive Spectroscopy (EDS), Elemental Analysis

- Custom solutions available