Device Physical Analysis

In-Depth Analysis & Reporting

• Verify component performance & prevent failures

• Trust your product to perform in high-reliability applications

• Validate manufacturing processes

• Meet MIL-STD requirements for aerospace & defense

Device analysis gives you a detailed look inside a component to verify its physical integrity. Minute production flaws or weaknesses can compromise performance and lifespan. Prevent failures by identifying defects early in your process.

Meet mil-aero standards and requirements for testing processes with Spirit’s device analysis methods, including physical inspection analysis and materials composition analysis.

- MIL-STD-883

- MIL-STD-1580 (DPA)

Benefits of Our Services

Our mission is to identify your problem and provide actionable steps you can take to improve your processes.

Detailed Reports

Clear identification of the root cause of failure

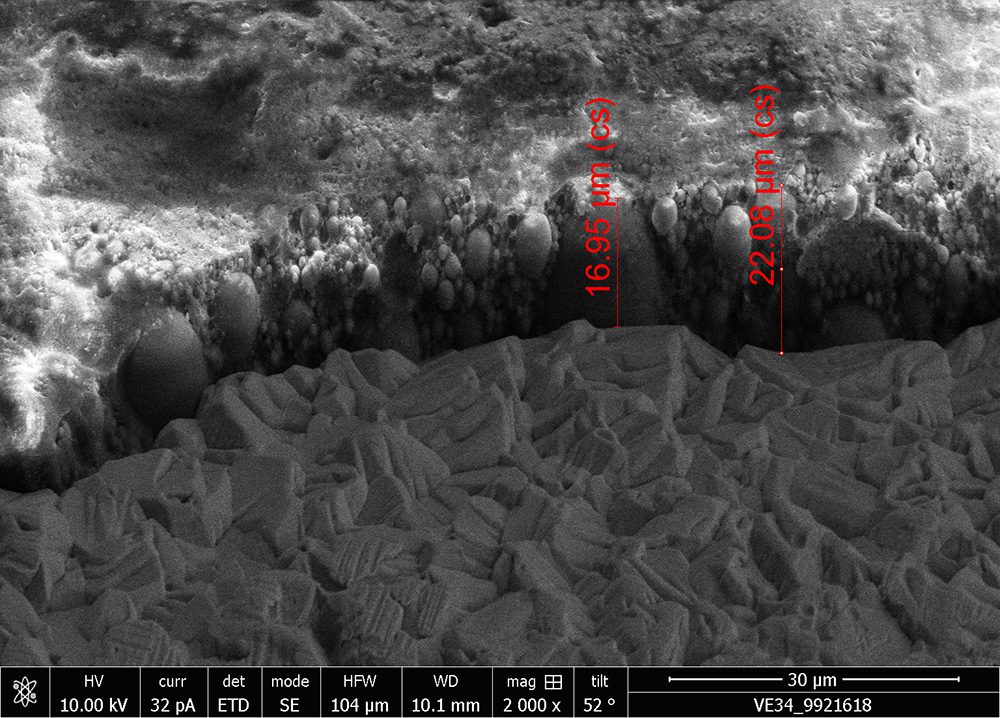

Photo Documentation

High-res imagery that supports our analysis

Fast Turnaround

24-hour quotes and quick delivery of analysis

Corrective Actions

We recommend how to resolve your problem.

Communications

Work directly with our USA-based engineers

Quality

ISO9001:2015 certified & ITAR registered

Authorized Distribution + Device Analysis

Spirit Electronics is uniquely positioned as an authorized distributor capable of working with your OEM to validate and improve manufacturing processes with device analysis findings.