Own Your ASIC,

Own Your Supply Chain

ASICs (application-specific integrated circuits) are a smart investment when you know your product’s exact application and functional requirements.

ASIC programs can take multiple IC functions and design, manufacture and program a single IC that can do it all. From processing to sensing to memory and power management, a single multi-function ASIC can reduce the demands and lead times in your supply chain.

And best of all, you own that ASIC component from design to application as your own IP.

Sean MacDonald, Director of Technical Sales at Spirit Electronics, explains the processes and benefits involved in ASIC programs.

Why ASICs

Own Your IP

Faster Fab during Allocation

Lean & Flexible Supply Chain

One Multi-Function IC

DLA Commercial Lab Suitability for MIL-STD-883

- Stabilization Bake 1008 A-D

- Temperature Cycling 1010 A-E

- External Visual 2009

- Ultrasonic Inspection of Die Attach 2030

- HAST – Biased JESD22-A110

- HAST – Unbiased JESD22-A118

Get Started —

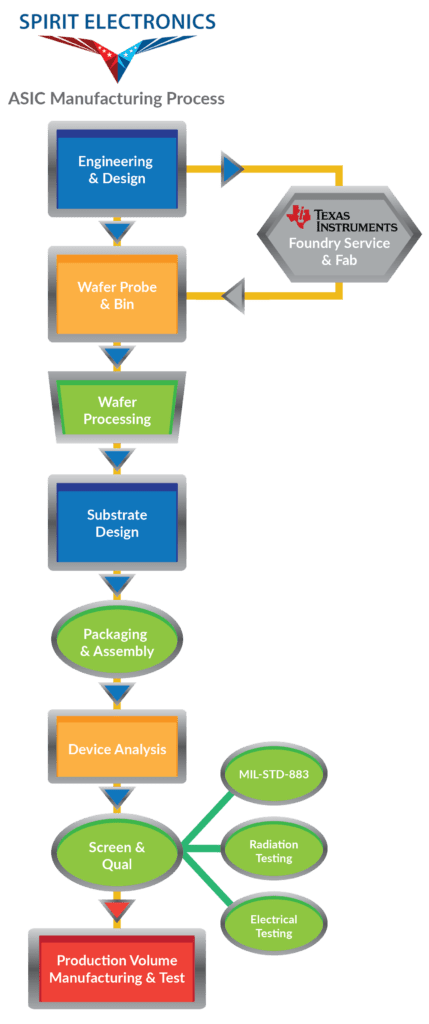

Bring us your application needs and design. We’ll collaborate on inputs, outputs, functionality, then we manage it ALL after the design kickoff.

Spirit manages your ASIC program from design to delivery.

Requirements—ASICs are designed to meet application-specific requirements. We help you define ASIC requirements and make sure your product design is engineered to support your application.

IP & Tech Nodes—Spirit is an authorized supplier to industry-leading OEMs. Our ASIC engineering experts have large IP libraries for reference in the design stage. Your ASIC has to meet your requirements, but you don’t have to design from scratch.

Logistics & Planning—Our agile logistics and program management take your ASIC design and source a foundry, raw materials and service providers. You decide the design, we deliver your ASIC ready for your production line.

Create an ASIC family—Capitalize on your design investment by creating multiple ASICs to support a range of product applications and performance requirements.

Fab & Production—Spirit Electronics now offers foundry services in collaboration with Texas Instruments (TI). Spirit works with the foundry for quantity management and to maximize space on the wafer for each production run.

Substrates—Choose from ceramic or organic substrates to mount your ASIC die. We can manage your substrate supply or work with one of our partners.

Substrate characterization—Spirit’s test capabilities can characterize substrates for thermal requirements. Substrate characterization can enhance ASIC reliability and performance.

Packaging—Spirit will package your ASIC into its final form. We work with your packaging supplier or can source the package from one of our trusted partners.

Wafer Probe—Our advanced electrical testing capabilities allow us to probe ASICs on each wafer. Wafer probe eliminates die failure but also determines the electrical limits of each ASIC.

Bin & Sort—Sort ASIC die into performance ranges based on electrical characterization. Select the highest-reliability ASICs for your most critical applications. Our test experts can help define test ranges to optimize ASIC performance.

SAM Analysis of Final Packaging—Analyze bonds and packaging to prevent voids in your finished ASIC chip. Know your ASIC will be packaged for the application’s environmental conditions.

Electrical Test—Electrical characterization at ASIC or a system level guarantees peak performance in your application’s conditions.

Burn-in, stress testing, temp cycling—Validate your ASIC performance for any environment, whether in defense applications, ground conditions, or the harsh conditions of space.

Radiation testing—Radiation testing can characterize your ASIC for rad-hard or rad-tolerant space applications.

MIL-STD-883 testing—Spirit is a qualified DLA commercial lab provider for MIL-STD-883.

You own your ASIC and your production schedule. ASIC programs support long-term production, even into EOL and legacy applications.

Nitrogen Storage—Spirit offers nitrogen storage options with cabinets and packaging. Our on-site nitrogen-generator supports optimal ASIC die and wafer storage to prevent oxidation. We can stock and store your ASIC ready to meet production schedules well in advance.

Wafer Banking—Proper wafer storage can extend and ensure long term viability.

We already have a provider for…

Already working with a partner on substrates, packaging or another step in the ASIC process? Spirit works with your partners to manage all program logistics. We save you time and budget from design to delivery, and you know where your ASIC is every step of the way.

Legacy Design and EOL Support

When a product goes end-of-life after long-term use, you know its essential applications and requirements. Design an ASIC to meet or even improve on that form, fit and function to keep production running.

Legacy ASIC programs can also benefit from improved design to incorporate new technology, alternative substrates or production processes.