XRF Analysis

Product Composition Visibility

Know your material composition meets product specs and standards with XRF analysis.

X-ray Fluorescence (XRF) testing shows you the exact ratios of the materials in your component. This nondestructive test is especially valuable for verifying tin-lead finishes in military-aerospace applications.

Our Hitachi EA6000VX and test engineers provide a full report of your component’s composition ratios alongside high-resolution images of your product down to 0.025 microns.

Higher Accuracy

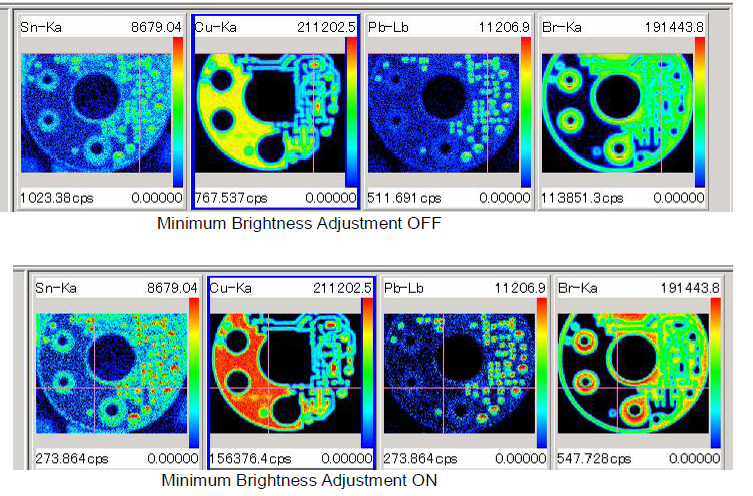

Our Hitachi EA6000VX is not your typical handheld, point-and-shoot XRF machine. This high-sensitivity bench analyzer can measure composition across product surface areas as well as in microscopic detail.

The EA6000VX can measure material composition against industry standard samples. We report in minutes how your product compares to the standard.

Not sure what the composition of your product is? We also perform exploratory analysis to determine unknown material makeup.

Detailed Analysis

Our engineers can measure your product in detail from individual leads and pin-point locations to the internal layers of your product. Measure and verify product features and coatings thickness.

With advanced imaging, we can map your product’s internal elements without disassembly. Examine connections, markings, leads, and layers within your part. High resolution images of part mapping are printed to your analysis report.

XRF Applications

- Composition analysis

- Solder analysis, especially mil-aero SnPb finish requirements

- Coating thickness measurements

- Mapping and connection inspection (visibility down to 0.025 µm)

- Restricted materials testing

- Void detection

- Contaminant detection

- Counterfeit prevention

- Receiving inspection

Spirit Speed

Save time on your PO delivery with our one-day turnaround. Instead of shipping products out to a third party or needing your internal work order, we complete our XRF inspection and analysis while your product is in house before we ship to you.

We manage this critical inspection for you, and your product arrives on your dock qualified and ready for use.

Warehouse & Lab Protections

Your product is protected in our facility from inventory to XRF bench to packaging. Our ESD control program and environmental controls are in place in our lab to protect your product during analysis.

Learn more about Spirit’s full offering of component and system-level test and screening services.

Failure Protection

Products testing outside of specifications or standards pose a failure risk. Improperly leaded finishes can result in whiskering over time.

If your product fails analysis, you can take immediate action to refinish leads, or in the case of failed connection mapping, disqualify an entire lot. Ask us about our testing warranty protection to prevent failures from impacting cost and production time.