There are many hurdles that must be overcome when attempting to introduce a new electronic gadget to the market. The trials and tribulations of creating a prototype and developing a unique, compelling solution to a consumer problem are only the first step in a long series of trials; with a working prototype in hand, a manufacturer must perform extensive testing on their new product in order to ensure reliability over its lifespan, a process that often leads to several costly design revisions before the product is even released for general consumption. Even after a reliable product has been produced, the qualification process for the new device is not over; unless the manufacturer is making a type of device that is specifically exempted, the new product must undergo RoHS certification or be barred from sale in the vast majority of markets.

Implemented in July of 2006, the Restriction on Hazardous Substances Directive (RoHS) is a European Union edict that places stringent limitations on the use of six substances found in many electronic devices. These substances were chosen to be restricted, since they are the greatest contributors to environmentally hazardous electronic waste. The heavy metals, like lead and mercury, in “e-waste” can contribute to groundwater poisoning, while other materials like the polychlorinated biphenyls found in scrap electronics are highly carcinogenic. Worse still, undeveloped countries often import large quantities of e-waste, then recycle it using crude methods that release untold quantities of carcinogens and neurotoxins into the air. Remnants are washed away into rivers and eventually to the ocean.

RoHS aims to remedy this highly toxic situation; however, there are additional ramifications to this directive for producers of electronic components, since the onus falls upon them to ensure that their devices are in compliance with the new restrictions. The RoHS certification process is one way to demonstrate this type of compliance; this process often involves extensive analytical work to ensure that none of the prohibited materials have unintentionally made their way into the end product.

Performing a RoHS certification involves a deep-dive into the composition of the constituent parts of a device – extensive analysis must be performed to ensure that the types of solder used to mount components onto the board, the fire-retardant material in the board itself, and even the protective coating used to shield delicate electronics from harsh environments are all free from proscribed elements.

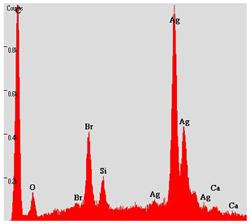

This analysis can take many forms – x-ray fluorescence is often used to examine plating on components to look for traces of lead, while more precise energy dispersive spectroscopy techniques might be employed to characterize solder joints. These tests are sufficient for the elemental substances restricted by the RoHS directive; for the molecular compounds, it is often necessary to use techniques like Fourier transform infrared spectroscopy, which uses a single-wavelength infrared light source to excite the atoms in a molecule, causing bonds to vibrate and oscillate in characteristic patterns that can be used to positively identify a given material at the molecular level.

Though ensuring that the restricted materials are absent from a given part may be the primary goal of an RoHS certification, a thorough analysis doesn’t stop there; changing to “environmentally friendly” materials may have a detrimental impact on product reliability, a possibility that should also be explored during the certification process.

The substitute materials used for creating RoHS compliant devices (lead-free solder being chief amongst them) often have different characteristics than those they replace. Reflow times and temperatures must be changed to accommodate the different demands of the new materials, potentially causing additional stress that may drastically reduce the lifespan of the product. These materials also react differently to prolonged thermal stress, making more robust cooling systems necessary for RoHS compliant products that generate large amounts of heat. Further, improperly formulated solder or component plating may lead to the formation of “tin whiskers”, monocrystalline extrusions of conductive tin that can break free and create short circuit conditions between the leads of a device, potentially resulting in a catastrophic failure.

Due to the increased risks inherent in making a transition into RoHS certification, it is often necessary to perform additional characterization of the device to avoid succumbing to any of the aforementioned pitfalls. Fortunately, many labs that can perform RoHS certification inspections also have the capability to aid with the sorts of reliability analysis (thermal stressing, cross-section, and so on), thereby providing a complete picture of the impact of a RoHS transition.

Though RoHS certification may seem intimidating, it is an absolute necessity for any company wishing to be competitive in the electronics industry; after all, without RoHS certification, the doors of countless markets will remain closed to any new product. Fortunately, there are IC failure analysis labs that can offer in-depth, comprehensive analysis of a new product, providing a helpful guide through the tangles of the RoHS auditing process.